светло-желтая сумка через плечо для женщин кошелек бродяги с маленьким мешочком

Пользовательские другие материалы, подкладка, цвет, фурнитура и логотип и т. Д. приветствуются.

Feb 29, 2020

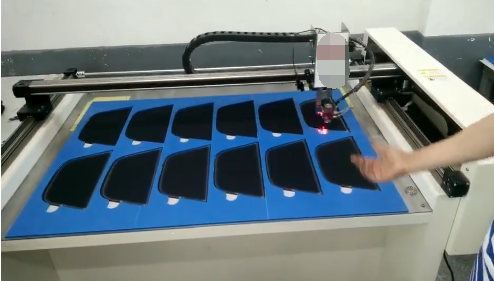

1.Cutting

Cutting is the first step during the production,including cutting leather and inner fabric material.

Main material including Genuine Leather(eg:cowhide/lambskin) and Vegan Material(eg:PU/canvas/nylon),which is different in cutting.

For example,genuine leather is use artificial cutting,cause the real leather always with some scars,we need to avoid the defective parts, that's why genuine leather with larger loss during cutting.Vegan material always be cutting by machine.

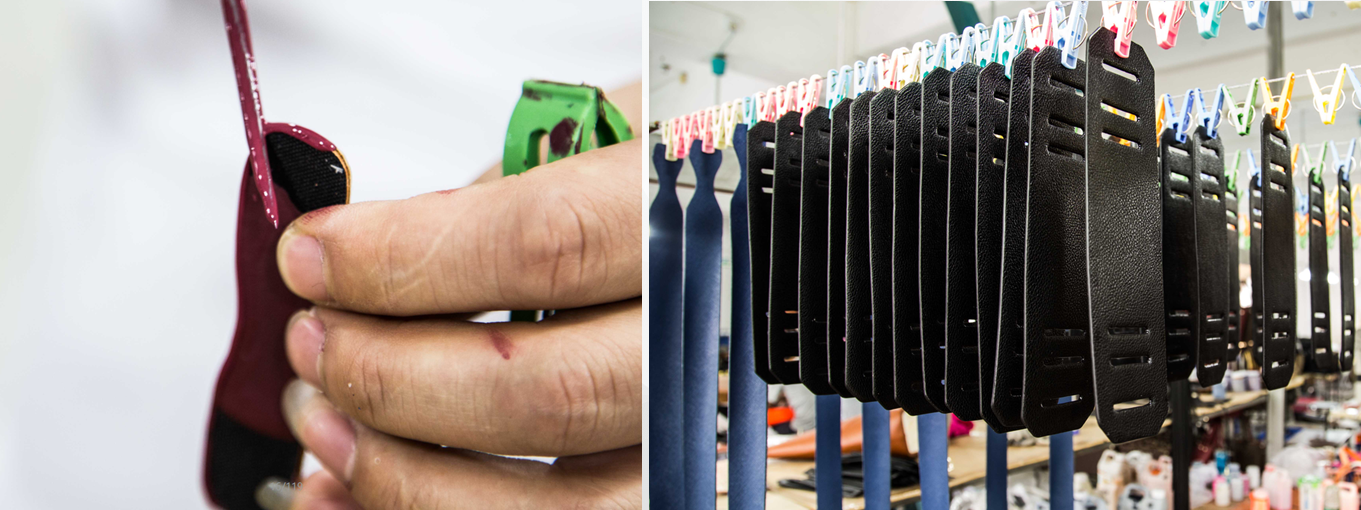

2.Scraping

Scraping mean to remove the plush on the bottom of the leather. Also,some kinds of leather are thicker, we need to scraping it into the suitable thickness for making sure it could works well on production.

3.Gluing

Some designs are the structured styles,leather itself could not able to make it stand up easier so that we need to add the inner lining material for supporting the whole design.Gluing on the bottom of the leather then assembling the inner lining material on it to make it stronger enough.Diffferent materi with different thickness and different touching feeling,we're usually accroding to customers demands for choosing it.

4.Painting

Painting:Adding the oil on leather edges to make it looks well. Different painting oil , the price is very different . For the same design ,if with the poor quality painting oil , the cost is about USD1 ;But if with the high quality painting oil , the cost is about USD3. Of course , the poor quality painting oil just can last 2-3 months ; the good quality painting oil can last very long time , at least 5 years .

5.Adding Logo

Custom logo including metal logo/embossed logo/printed logo.

Metal logo could do any usual colors like gold/silver/light gold/gunmetal/light gunmetal color.

Embossed logo could do blind/silver/gold/light gold foiled embossing.

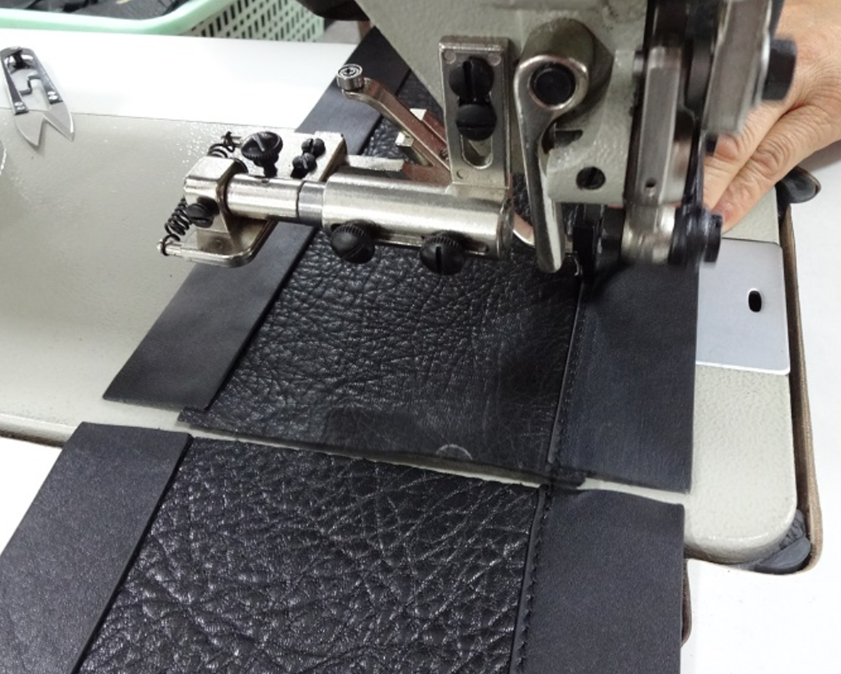

6.Stitching

Stitching is the most important part during production.

In this step,we need to pay more attention on every details.

7.Installing Hardware

As we all know that there always have many hardware accesseries on the bag,some hardware need to install before stitching,others will install after that. Different hardwares will be installed by different machines.

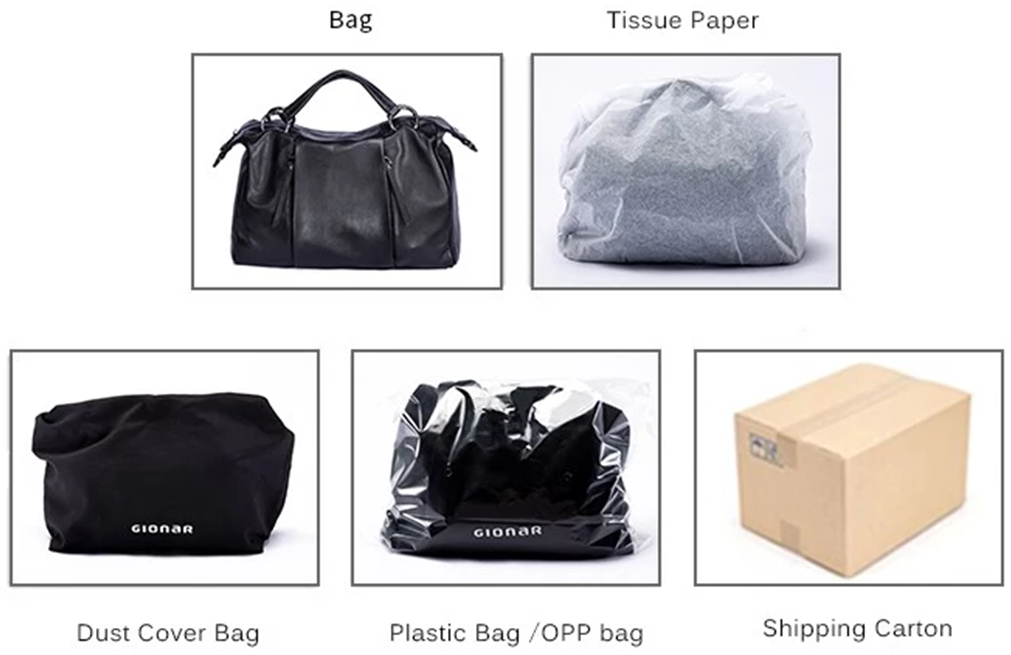

8.Cleaning&Packaging

*Cleaning&Packaging is the last part on production,in this part we need to cut the extra stitching,clean the stains/glue and some other flawed areas.Then, we could packing the bags.

*Packing Details including tissue paper+dust bag(if required)+plastic bag+sticker(if required)+outside carton

The information is from gionar.com

Предыдущий :

Custom LOGO/ LOGO TypeСледующая :

What is the RPET Material?Пользовательские другие материалы, подкладка, цвет, фурнитура и логотип и т. Д. приветствуются.

Пользовательские другие материалы, подкладка, цвет, фурнитура и логотип и т. Д. приветствуются.

Пользовательские другие материалы, подкладка, цвет, фурнитура и логотип и т. Д. приветствуются.

черные винтажные кожаные сумки для ноутбука

2020 новая дизайнерская сумка с плетеной ручкой

женские сумки из натуральной кожи с тканой ручкой

спортивная сумка на заказ из коровьей кожи с карманом для обуви

2020 новый мужской винтажный кожаный портфель

Авторское право © 2015-2024 Guangzhou Gionar Leather Products Co., Limited.Все права защищены

/ Карта сайта / XML